Cap Lining Materials

Cap lining materials are inserted into the caps or closures of containers being supplied for use in the packaging process. These liners offer multiple benefits, such as leak-proofing the container, maintaining adequate oxygen and moisture within the container so as to prolong the product’s shelf-life, and serving as tamper evidence in case of product disruption.

Specialized cap lining machinery is needed to place these cap lining materials. For cap manufacturers especially, having machines for this purpose is vital. Some end users may also benefit from investing in such machines when the demand for their product reaches more than 10,000 lined caps per day.

Specialized cap lining machinery is needed to place these cap lining materials. For cap manufacturers especially, having machines for this purpose is vital. Some end users may also benefit from investing in such machines when the demand for their product reaches more than 10,000 lined caps per day.

There are a multitude of industries which make use of cap liners. Food industries in the 21st century cannot do without cap wad insert machine because the rigors of transport, handling and distribution could adversely impact the products. Coffee, wine and other beverage manufacturers and distributors are common users of these cap lining materials. Cosmetics also use them both for sanitary reasons and to keep the product’s shelf-life.

In the field of pharmaceuticals, cap lining materials are also of utmost importance. Tamper evidence can be provided in an economical and consumer-friendly manner without compromising the integrity of the product in the process. Its significance is even highlighted by the Food and Drug Administration’s (FDA) guidelines in the use of such materials for the safety of the public.

Agricultural chemicals also use an assortment of cap lining materials. Certain types of liners are applicable for solvents, alkalis and acids, making them ideal for these hazardous substances.

The Induction Sealing Process

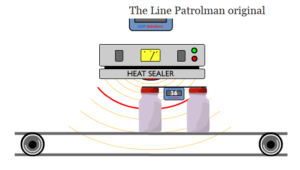

In order to adhere the cap liners onto the containers, cap lining machines will introduce the containers to the induction sealing process.

Induction sealing begins with the cap and its associated liner arriving to the production line. The liner is placed within the cap and, along with the filled container, will go down the conveyor line until the components reach the induction sealing head. This part of the machine will introduce an electromagnetic field which can permeate the cap and the aluminum layer within the liner. This field will then generate enough electric current to melt part of the liner, effectively adhering it onto the mouth of the container. The container is then allowed to cool down as it continues its way down the conveyor belt.

The impressive thing about the induction sealing process is that, once the container reaches the consumer and the liner is removed, it cannot be reattached onto the container without specialized cap liner insertion machines.Lining Machinery and Cap Liners Supplier This provides another level of tamper evidence for the benefit of the consumer.

Choice of Cap Liner Machinery

Cap lining material can be supplied in either a pre-cut or roll format. Choosing between these options will depend on the scale of the project and the budget for equipment, with many options and outcomes available. For the smallest and the largest of cap lining projects, there are pre-cut cap liner machine options which can meet the demands of production, while being the more economical option for the manufacturer. For medium to large scale operations, roll-form lining machines are available.

Sometimes however, the choice of machinery will depend on a particular project and its lining requirements. Certain specifications and processes may need to be met for these projects, and so, reaching out to our team can help you find the best machine and cap liner for your product.

Benefel Pty Ltd. and Adeneli Packaging

Our teams at Benefel Pty Ltd. and Adeneli Packaging can help you with your cap lining material needs. Our experts are on standby to take your calls and chats. Whatever product you may have, we have the perfect liner material for you. Product consultation is free and we are happy to develop partnerships with our customers by supplying consumable products that work well with packaging machinery.

Follow Us