Peels and Seals Liners

Manufacturers have to be aware of how product sealing can impact consumers. “Seal For Your Protection” Packaging is widely utilized in different fields, employing product seals that can deliver both the required safety elements for the consumer while giving them the satisfaction of a well-made product.

When it comes to tamper-evident seals, any form of disruption on the liner can be a sign to the consumer of any untoward tampering. Consumers then choose to either discard the product or report the issue to the proper authorities, especially when it comes to pharmaceuticals’ tampering.

In the pharmaceutical industry, “seal for your protection” packaging, otherwise known as tamper-evident packaging, is prominent. So much so that even the Food and Drug Administration (FDA) has strict protocols that manufacturers must adhere to, in order to protect the safety of the public. The FDA has defined this type of packaging as “one having one or more indicators or barriers to entry which, if breached or missing, can reasonably be expected to provide visible evidence to consumers that tampering has occurred.” Strict requirements are imposed on manufacturers and distributors of pharmaceuticals in the interest of the people.

Besides the pharmaceutical industry, the food and beverage industry also benefit from the “seal for your protection” packaging. Not only do the cap liners found in these foods’ containers serve as freshness seals, but they also allow for any evidence of package disruption by an outside force.

Product Sealing and Cap Liners

Cap liners serve four basic functions:

- Protect against fluctuations in moisture and oxygen exposure of the product

- Prevent product leakage during transportation and handling

- Preserve the product’s freshness and maintain its shelf-life

- Provide evidence of any tampering of the product

In general, product seals can be classified into one- or two-piece liners. These two vary in their composition and applications.

One-piece liners are more often used on dry goods and powders and are applicable for one-time use packaging. Products which benefit from this type of cap liner include those expected to be consumed immediately upon opening.

Two-piece liners, on the other hand, are more commonly utilized for liquids and products meant to be opened and reused multiple times over an extended period of time. These liners are not discarded on opening of the product and instead reside within the cap of the container in order to maintain the container’s leak-proofing and preserve the product’s shelf-life.

Both types of cap liners have their own advantages. Whichever type of product seal you choose for your product, both types must undergo the induction sealing process in order to adhere onto the mouth of the container.

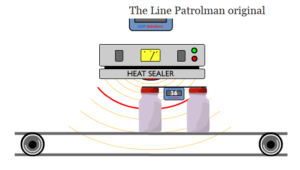

Induction Sealing For “Peels and Seals”

In the induction sealing process, a cap with its respective liner comes into the conveyor line. The filled container is paired with the cap, and both make their way down the production line until they reach the induction sealing head. This induction sealing head is able to emit an electromagnetic field which can permeate both the cap and the aluminum foil layer within the liner. The electric current generated is able to melt the liner film, allowing for adherence of the liner onto the container mouth. The liner is then allowed to cool as it makes its way down the next part of the conveyor line.

In the induction sealing process, a cap with its respective liner comes into the conveyor line. The filled container is paired with the cap, and both make their way down the production line until they reach the induction sealing head. This induction sealing head is able to emit an electromagnetic field which can permeate both the cap and the aluminum foil layer within the liner. The electric current generated is able to melt the liner film, allowing for adherence of the liner onto the container mouth. The liner is then allowed to cool as it makes its way down the next part of the conveyor line.

No matter the type of cap liner, it is imperative that the seal be adequate in doing its job in order to not jeopardize the trust of the consumer with the product. With the induction sealing process, the liners are able to do their jobs of sealing in freshness while keeping tampering at bay.

Benefel Pty Ltd. and Adeneli Packaging

Our teams at Benefel Pty Ltd. and Adeneli Packaging can help you with your “seal for your protection” packaging. Our experts are on standby to take your calls and chats. Whatever product you may have, we have the perfect liner material for you. Product consultation is free and we are happy to develop partnerships with our customers by supplying consumable products that work well with packaging machinery.

Follow Us