Sealing Glass Jars through Capless Induction Sealing

When it comes to sealing glass jars, specifically those with metal lids, a big hurdle is adequate sealing. In the past, this task was insurmountable, and for many years, the induction sealing process was limited to plastic containers with plastic caps. These days, with the introduction of more wattage in better-functioning equipment, sealing glass jars is possible with capless induction sealing.

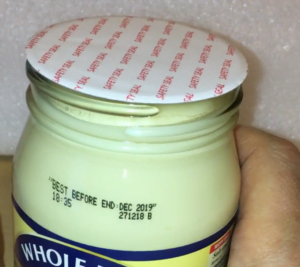

This type of process allows seals to be leak-proof, making handling and transportation of said products easier on everyone involved. The induction seals are hermetically generated and are able to prevent the products from being affected by outside moisture and oxygen fluctuations. This keeps the contents fresh for longer, able to meet and even extend the shelf-life of the product. An added advantage is its tamper evidence. The nature of the seal itself allows for any disruption to be easily noticed, for the benefit of the consumer.

These aspects are time-tested and proven advantages of induction sealing. As such, the public puts their trust towards these products. And now, with the innovation of capless induction sealing of glass jars, more and more avenues are being opened up for different industries.

Sealing Products with Metal Lids

When product manufacturers choose to use metal lids instead of the more conventional plastic type, the induction process must be adapted to suit their needs. The classic induction process finds its liners inserted within the cap of the container. These components pass under an induction sealing head which generates an electromagnetic field which can permeate the cap of the container without damaging it. This field generates enough electric current to melt part of the liner, adhering it firmly onto the mouth of the container. The now-capped container then cools as it makes its way down the conveyor belt.

When product manufacturers choose to use metal lids instead of the more conventional plastic type, the induction process must be adapted to suit their needs. The classic induction process finds its liners inserted within the cap of the container. These components pass under an induction sealing head which generates an electromagnetic field which can permeate the cap of the container without damaging it. This field generates enough electric current to melt part of the liner, adhering it firmly onto the mouth of the container. The now-capped container then cools as it makes its way down the conveyor belt.

The downside of the traditional induction sealing process is that it cannot be used when the container comes with a metal lid. This is why these types of containers require a special mode of induction sealing process.

Through capless induction sealing, this problem has been remedied. An additional component is added to the equipment in order to apply the necessary pressure onto the liner while it is being adhered on the lip of the container. These additional sealing heads may come in different configurations, e.g., single or multiple heads. The sealing head is able to generate enough heat and pressure to adequately seal the container even without a cap.

Through this technology, as with induction sealing in general, many industries have branched out into international trades and commerce. The food and beverage industry is a foremost user of cap liners because of the freshness guarantee that comes with these products. The prolonged shelf-life also allows for international export without the issue of spoilage or leaks.

Another industry that makes full utilization of induction liners is the pharmaceutical industry. With the necessity of tamper evidence in mind, these seals are invaluable in packaging for these companies.

In the cosmetics industry, having properly sealed glass jars are not just for aesthetics, but also serve to prevent product contamination and help with handling of the products.

In the agricultural sector, these seals allow for containment of corrosive substances such as alkalis, acids and solvents, without compromising the safety of consumers.

In the agricultural sector, these seals allow for containment of corrosive substances such as alkalis, acids and solvents, without compromising the safety of consumers.

Benefel Pty Ltd. and Adeneli Packaging

Our teams at Benefel Pty Ltd. and Adeneli Packaging can help you with your sealing glass jars needs. Our experts are on standby to take your calls and chats. Whatever product you may have, we have the perfect liner material for you. Product consultation is free and we are happy to develop partnerships with our customers by supplying consumable products that work well with packaging machinery.

Follow Us