Tamper Evidence Seal

Product seals have different applications in the multiple fields they are utilized in. The most basic functions of cap liners include maintaining a product’s shelf-life by serving as a barrier against oxygen and moisture from the surroundings, preventing any leakage through proper adherence either on the mouth of the container or within the cap, keeping the product fresh and unaffected during transportation and handling, and providing additional branding benefits through the cap liner label. But one aspect which may be overlooked is that these products also come with the label of “sealed for protection.”

Product seals have different applications in the multiple fields they are utilized in. The most basic functions of cap liners include maintaining a product’s shelf-life by serving as a barrier against oxygen and moisture from the surroundings, preventing any leakage through proper adherence either on the mouth of the container or within the cap, keeping the product fresh and unaffected during transportation and handling, and providing additional branding benefits through the cap liner label. But one aspect which may be overlooked is that these products also come with the label of “sealed for protection.”

This seal is the manufacturer’s answer to the issue of product tampering. Product seals come with this label because it announces to the consumer that the product has tamper evidence technology, effectively safeguarding the consumer from any outside disruption to their product.

Peels and Seals as Tamper Evidence

The Food and Drug Administration (FDA) has made clear guidelines for manufacturers and distributors regarding their product seals. Through the FDA’s attempt at regulating the approach of manufacturers with how they show product tampering, the public is now aware of the importance of the “sealed for protection” liner approach.

Any breach in the product seal is easily demonstrable through this method and the consumer is alerted of any incidents of tampering. This greatly elevates the public’s safety against any damage or disruption to the products they consume.

In the pharmaceutical industry, tamper evidence is demonstrated through the cap liners in containers, showing a “peel and seal” approach in that once the consumer opens the product, they are shown an intact, multilayered seal whose upper part they can remove and discard. The remaining part can then be replaced within the cap of the container, thereby protecting the product from moisture or oxygen exposure for the remainder of its shelf-life.

In the pharmaceutical industry, tamper evidence is demonstrated through the cap liners in containers, showing a “peel and seal” approach in that once the consumer opens the product, they are shown an intact, multilayered seal whose upper part they can remove and discard. The remaining part can then be replaced within the cap of the container, thereby protecting the product from moisture or oxygen exposure for the remainder of its shelf-life.

For food products and beverages, the “sealed for protection” cap liners are equally important. Providing the public these cap liners as a means for protection boosts the people’s trust towards the manufacturers of the products they consume.

Induction Sealing Process for “Sealed for Protection” Packaging

In order to give the best possible results for product sealing, production must both be monitored from the start, and end with a good, reliable induction sealing methodology.

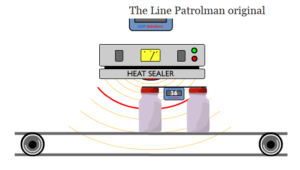

Induction sealing entails a series of steps to ultimately facilitate adherence of the product seal onto the mouth of the container. The cap and its corresponding liner arrive at the production line. Along with the already-filled container, these components move down the line until they reach the induction sealing head. This part generates an electromagnetic field which can pass through the cap and into the aluminum layer found within the liner. This permeation melts the liner and seals the product within. This hermetic seal is then allowed to cool while the container continues to move down the production line.

Induction sealing entails a series of steps to ultimately facilitate adherence of the product seal onto the mouth of the container. The cap and its corresponding liner arrive at the production line. Along with the already-filled container, these components move down the line until they reach the induction sealing head. This part generates an electromagnetic field which can pass through the cap and into the aluminum layer found within the liner. This permeation melts the liner and seals the product within. This hermetic seal is then allowed to cool while the container continues to move down the production line.

The great advantage of induction-sealed containers is that the liners themselves, while being resilient in their own composition, cannot be reattached once removed from the container mouth. That is, anyone who decides to tamper with said container will need specialized product sealing equipment to reattach the liner onto the container. Therefore, this form of “sealed for protection” packaging is a very reliable way of protecting the product and subsequently, the consumers.

Benefel Pty Ltd. and Adeneli Packaging

Our teams at Benefel Pty Ltd. and Adeneli Packaging can help you with your “sealed for protection” packaging. Our experts are on standby to take your calls and chats. Whatever product you may have, we have the perfect liner material for you. Product consultation is free and we are happy to develop partnerships with our customers by supplying consumable products that work well with packaging machinery.

Follow Us