Capless Heat Induction Seals

Heat induction seals are cap lining materials found between the cap and the mouth of the container. These heat seals keep the freshness of the product by keeping moisture and oxygen from infiltrating the product. They act to prolong the product’s shelf-life and prevent any leakage. An added benefit is the tamper evidence provided by induction foil sealing in order to protect the consumers from any outside disruption.

Many industries make use of heat induction seals. Food and beverage industries are some of the foremost users because with the globalization of exportation and importation of their products, manufacturing and distribution could possible disrupt product integrity at any point in the process. Any issues during handling can lead to catastrophic results for both the manufacturer and distributor, and so, having heat induction seals to protect these products are a lifesaver.

Many industries make use of heat induction seals. Food and beverage industries are some of the foremost users because with the globalization of exportation and importation of their products, manufacturing and distribution could possible disrupt product integrity at any point in the process. Any issues during handling can lead to catastrophic results for both the manufacturer and distributor, and so, having heat induction seals to protect these products are a lifesaver.

In the pharmaceutical industry, induction seal liners are also of utmost importance. For these kinds of products, the need for adequate tamperproofing and tamper-evidence cannot be overstated. The heat seals are so important that the Food and Drug Administration (FDA) even has set guidelines for tamper-evident seals, all for the benefit of the consumer.

Other industries also make full use of induction seal liners. For cosmetics, heat induction seals help preserve freshness of the product while also keeping the processing of the cosmetics sanitary. In agriculture, chemicals which were once difficult to contain safely, are now easily contained and distributed. Certain types of induction seal caps are capable of withstanding the abrasive properties of chemicals, thereby allowing for proper sealing of these materials.

The Induction Sealing Process

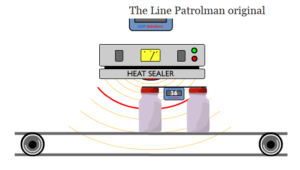

Heat induction sealing begins with the acquisition of the caps and their associated liners. These caps make their way to the production line and, along with the already-filled containers, continue through the conveyor belt until they reach the heat induction sealing head. This component generates an electromagnetic field which can permeate the cap and the aluminum foil layer found within the induction liner. The field is able to generate enough of an electric current to melt the part of the liner in contact with the mouth of the container, effectively sealing the product and preventing any contamination of the products therein. The container then cools down as it continues down the line.

Key Benefits to Induction Sealing From Benefel Pty Ltd. and Adeneli Packaging

- The sealing process can lessen incidence of product contamination at any point in the production chain.

- Heat induction sealing can add significantly more force when pressing the liner onto the container opening than what conventional induction sealing can provide. This results in a much better and more even contact of the liner.

- 100% visual inspection of the heat induction seal for quality assurance purposes is possible.

- On request, the seal integrity can be increased even more by dead-folding the edges of the seal around the lip of the container.

- Heat induction sealing can eliminate the need for multi-layer cap lining or a separate foam liner placed in the cap.

- Dust issues associated with multi-layer cap lining material can be eliminated with the use of heat induction sealing instead.

- Direct purchase of the cap lining material means that there are no markups or extra charges on your end.

- We can organize for your own logo or print message to be placed onto the heat induction seal, all at a very competitive price.

Benefel Pty Ltd. and Adeneli Packaging

Our teams at Benefel Pty Ltd. and Adeneli Packaging can help you with your heat induction seal needs. Our experts are on standby to take your calls and chats. Whatever product you may have, we have the perfect liner material for you. Product consultation is free and we are happy to develop partnerships with our customers by supplying consumable products that work well with packaging machinery.

Follow Us