Tamper Evident Seal Through Cap Liners

Cap liners are the key to meeting the ever-increasing demands of consumers for more and more products, without the issue of short shelf lives and leaking containers. These tamper-proof seals keep oxygen and moisture fluctuations at bay, maintain the freshness of the products within the containers and offer sufficient leak-proofing—an added advantage, especially for importations and deliveries. Cap liners also meet one of the most important requirements for product integrity: tamperseal.

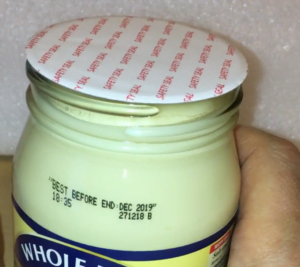

Tamper evident seals are achieved through the multiple layers that make up these cap liners, all working together to provide proof for the consumer if any untoward tampering of their newly-acquired product has happened.

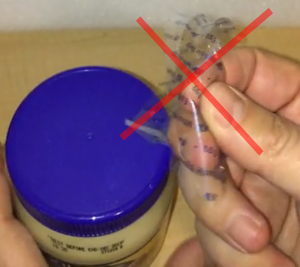

Through the process of induction sealing, a cap liner adheres to the container’s mouth. This tamper evident security seal cannot be reattached once removed, which is one way by which tampering can be demonstrated. And depending on the type of cap liner you choose for your packaging, resealing can still be achieved for subsequent usage, even if the tamperseal has initially been removed by the consumer.

Why Consumers Trust Cap Liners for Tamper Evidence

Tamperseal is provided by cap liners in many different products from a multitude of businesses. Everything from the food and beverage industry, to pharmaceuticals, all the way to agro-industry, consumers put their trust in manufacturers to deliver adequate tamper evidence for their products. This ensures the safety of the consumers and boosts the people’s confidence in the companies which provide these products. Any disruption in this tamper-proofing will alarm the consumer that an outside force has tampered with their product, enough that they will second-guess using the product. This mode of alarm could potentially save many lives.

from the food and beverage industry, to pharmaceuticals, all the way to agro-industry, consumers put their trust in manufacturers to deliver adequate tamper evidence for their products. This ensures the safety of the consumers and boosts the people’s confidence in the companies which provide these products. Any disruption in this tamper-proofing will alarm the consumer that an outside force has tampered with their product, enough that they will second-guess using the product. This mode of alarm could potentially save many lives.

Even the Food and Drug Administration (FDA) has issued guidelines regarding tamperseal in pharmaceuticals and foods to safeguard the public. This simply proves that tamper-proof seal stickers as a mode of tamperseal are recognized as an important public safety tool.

Induction Sealing in The Tamperseal Process

For cap liners to be placed properly, the induction sealing process must be employed. Induction sealing begins with the caps (and their cap liners) being loaded into the capper. Containers will then be filled with their respective products and capped. Down the conveyor line, these capped containers will continue until they reach the area below the induction sealing head. This part of the induction sealing machine will emit an electromagnetic field that penetrates the cap and the aluminum foil layer within its liner. This field permeates throughout the liner material, causing an electric current to melt the sealing film in the liner. The foil is then allowed to cool down as it leaves the induction field. Once cooled, the tamper-evident bottle seal fully bonds to the mouth of the container. At this point, even when the cap is removed, the cap liner will remain bound to the container’s mouth.

For cap liners to be placed properly, the induction sealing process must be employed. Induction sealing begins with the caps (and their cap liners) being loaded into the capper. Containers will then be filled with their respective products and capped. Down the conveyor line, these capped containers will continue until they reach the area below the induction sealing head. This part of the induction sealing machine will emit an electromagnetic field that penetrates the cap and the aluminum foil layer within its liner. This field permeates throughout the liner material, causing an electric current to melt the sealing film in the liner. The foil is then allowed to cool down as it leaves the induction field. Once cooled, the tamper-evident bottle seal fully bonds to the mouth of the container. At this point, even when the cap is removed, the cap liner will remain bound to the container’s mouth.

Once the container is opened by the consumer, the induction-sealed cap liner will adequately show evidence of tampering because this seal cannot be reattached once removed. Anyone who decides to tamper with the tamper-proof seal for bottles will need to use specialized equipment to reattach it to the container’s mouth—a feat for anyone without an induction sealing machine. Therefore, cap liners do their jobs well as tamper evident seals.

Benefel Pty Ltd. and Adeneli Packaging

Our teams at Benefel Pty Ltd. and Adeneli Packaging can help you with your tamper-evident seal material and machinery. Our experts are on standby to take your calls and chats. Whatever product you may have, we have the perfect liner material for you. Product consultation is free and we are happy to develop partnerships with our customers by supplying consumable products that work well with packaging machinery.

Follow Us